The Maotai Eco-Metaverse

Project Information

- Project Location:

- China Zhunyi, Guizhou

- Project Scale:

- 8 Hectares

- Design Time:

- June 2022

- Client:

- Kweichow Moutai Liquor Co., Ltd

- Award List:

- 2024 WAF GROHE Water Prize

- Related Papers

Project Profile

1. Project Statement

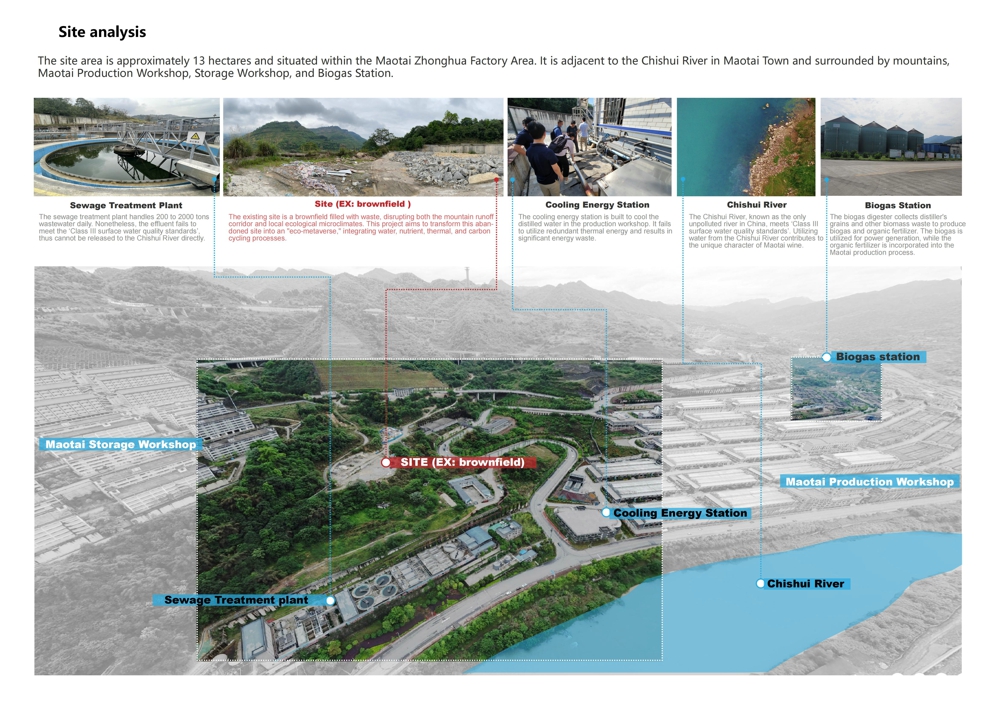

The Maotai Environmental Protection and Ecological Improvement Project, spanning 8 hectares and is going to be built by 2025 as a research and development project, is a bold testament to Maotai's dedication to merging sustainable practices with its esteemed tradition of liquor production. Developed by the architect for Guizhou Moutai Wine Co., Ltd., this initiative experimental project is set to transform the industry's environmental management by creating an ecosystem that fully integrates water, nutrient, carbon, and energy recycling. This visionary project is not just an undertaking of environmental compliance but a stride towards setting a new benchmark in industrial ecological integration.

2. Objective and Challenge

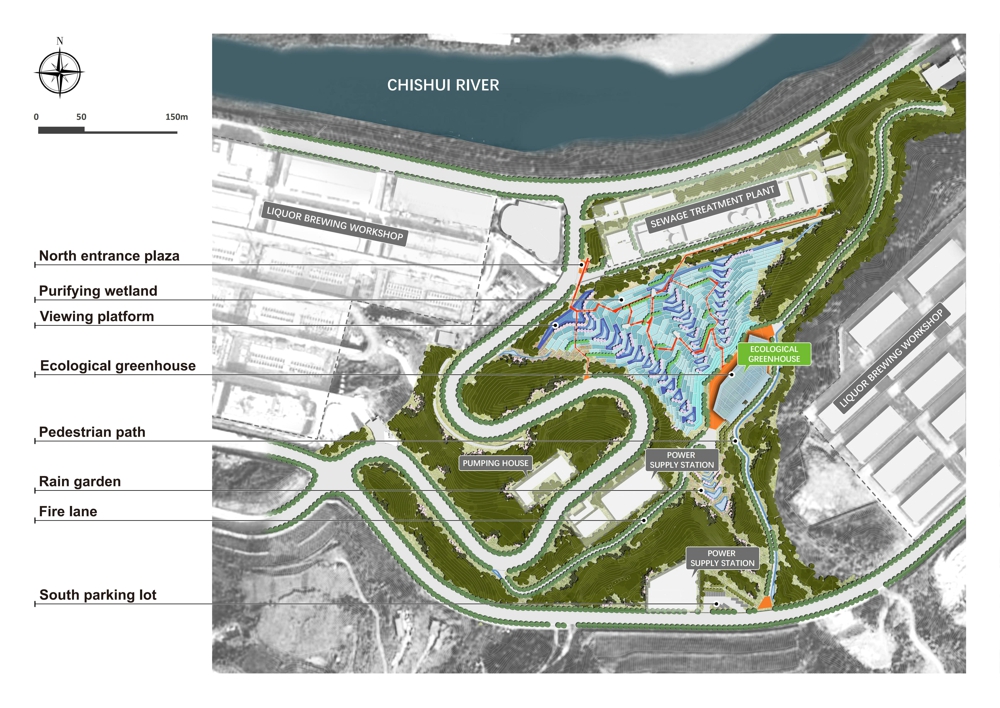

Situated in the heart of Maotai Town, this project confronts the significant challenge of managing daily outputs of 7,000 tons of sewage and industrial wastewater. This volume of effluent poses a substantial obstacle to meeting the Class II and III water quality standards of the Chishui River, highlighting the project's critical importance. Furthermore, the additional thermal pollution and energy demands stemming from the new distillery plants exacerbate the site's environmental pressures. Concurrently, as a central component of the endeavor, an abandoned hilly landscape filled with urban debris and solid waste was selected for an ecological experiment. Consequently, this initiative represents a pivotal step towards the sustainability of Maotai's water-centric operations. It ensures that the distillery's legacy aligns with modern environmental stewardship principles while also responsibly utilizing water and nutrients to transform the abandoned wasteland into a green paradise.

3. Design Strategy

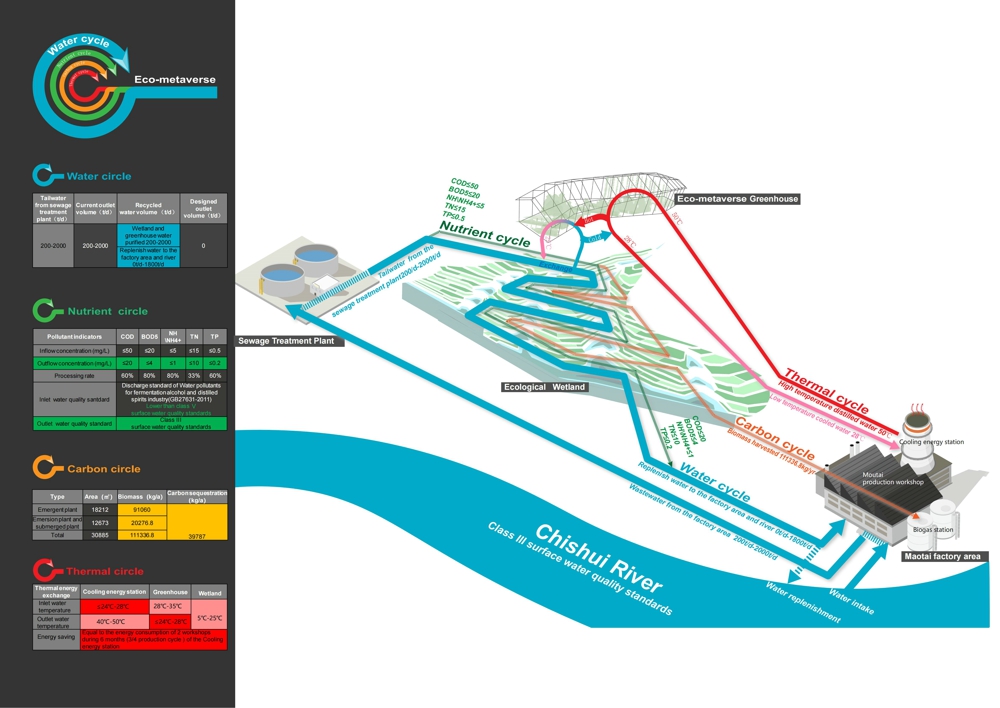

The Architect’s comprehensive response to these challenges is detailed in strategic implementations, each with measurable objectives:

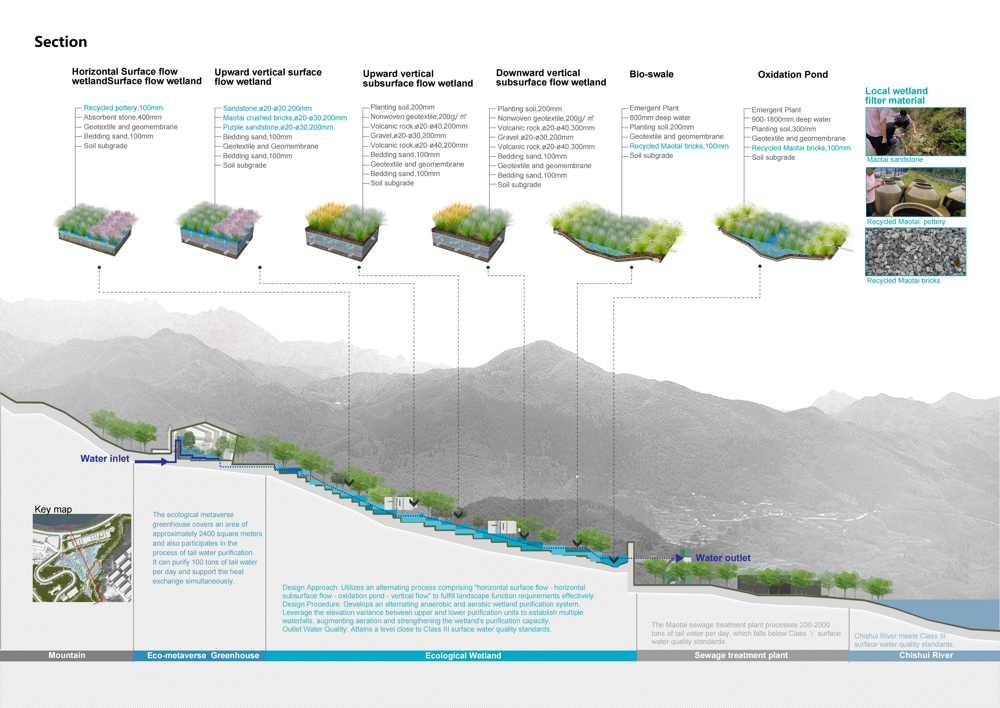

(1) Water Recycling: The system is engineered to treat and repurpose the distillery's wastewater, showcasing a processing capacity of 2,000-3,000 m³/d, supported by a lift pump capable of 140 m³/h. This infrastructure demonstrates an advanced commitment to managing and repurposing significant wastewater volumes.

(2) Nutrient Recovery: The purification wetland, divided into tailored zones for varied treatment processes—horizontal surface flow (20%), vertical surface flow (10%), upward (50%) and downward (20%) vertical subsurface flow—epitomizes the project's holistic approach to water purification and nutrient recycling.

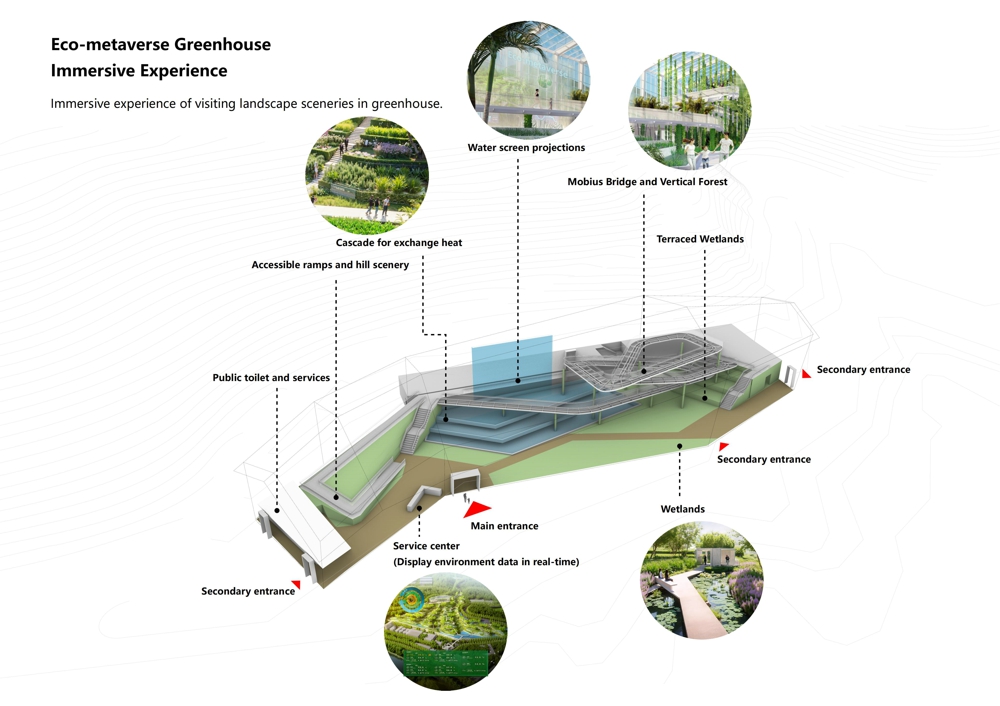

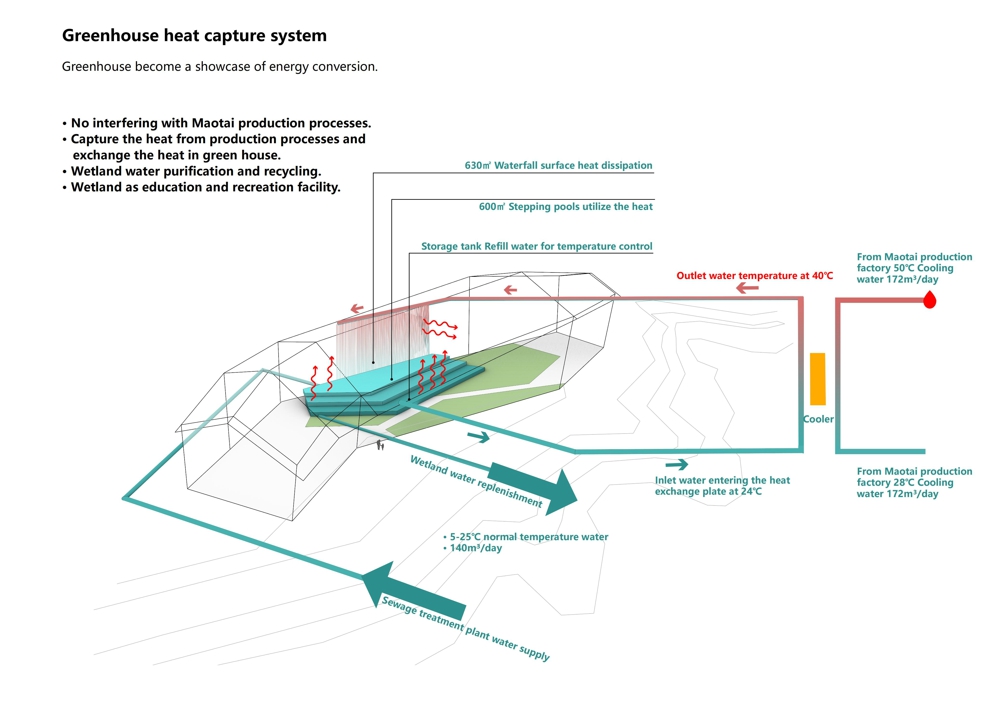

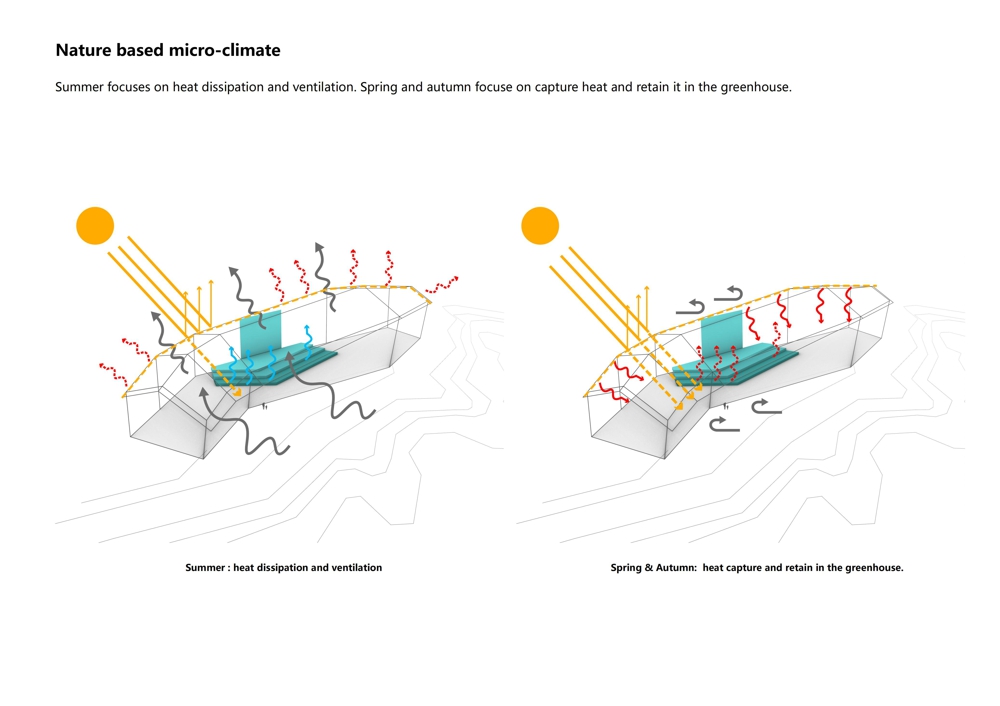

(3) Carbon Absorption and Heat Recovery: A 2,400 m² greenhouse, functioning both as a visitor center and a key component of the ecosystem, utilizes the wastewater's high-temperature (50°C) waste heat. This element underscores the dual objective of carbon sequestration and thermal energy recovery, further augmented by the integration of biogas technology.

4. Conclusion

"Green Distillation: Maotai's Pioneering Eco-Metaverse Project" serves as a paradigm of how traditional industries can embrace sustainable practices. Maotai's project not only addresses the immediate environmental impacts of distillery operations but also serves as a beacon for sustainable industrial practices globally. By detailing the project's achievements in water purification, nutrient recycling, carbon sequestration, and energy recovery, the article illuminates Maotai's broader commitment to a sustainable future—a testament to the possibility of harmonizing economic and environmental goals within the industrial domain. This initiative's success heralds a new era for ecological sustainability in the industrial sector, proving the viability of achieving environmental and economic objectives in unison.